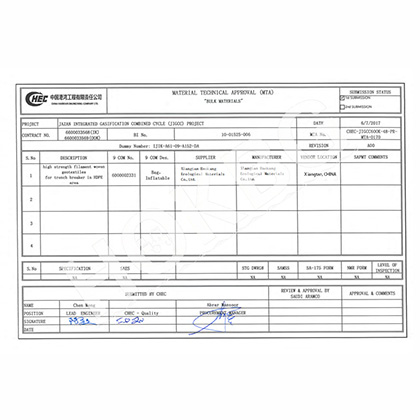

Project Overview

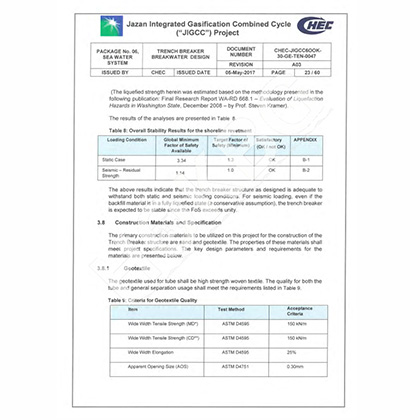

The Jazan Integrated Gasification Combined Cycle (JIGCC) seawater intake and outfall pipeline project is part of Saudi Arabia’s Jazan Economic City initiative. Its purpose is to supply seawater for industrial applications such as cooling, desalination and fire protection, as well as to discharge treated wastewater into the deep sea.

The project features the largest-diameter HDPE subsea pipeline installation in the world, with a total length of approximately 6,600 meters and a pipe diameter of 3.5 meters, capable of delivering 530 million liters of seawater per day.